1 / 5

The Cashmere Sweater - Archive

Inaugural production 2021. This version features a more accentuated neckline, cuffs and bottom hem, knitted in a 2x2 rib knit. It has since been updated by the 2022 version featuring a more minimalist 1x1 rib knitted neckline, hem and cuffs.

- Version

1.0

- Fiber composition

97% recycled cashmere 3% recycled wool

- Fiber grade

Grade A cashmere 16 micron

- Fiber certification

GRS

- Yarn count

Nm 2/12 in 1-ply

- Fabric construction

7 gauge, plain knit

We trace all our garments, component by component, process by process, and document every supplier involved in creating our garments.

How it's made

Packing

Romania

2022-11-01

Washing

Romania

2022-11-01

Linking

Romania

2022-11-01

Knitting

Romania

2022-11-01

Ply twisting

RITORCITURA DIANA DI LEGGIERI ANTONIO & C. S.N.C

Italy

-

Spinning

Italy

2023-05-08

Carding

Italy

2023-05-08

Shredding

Italy

2023-05-08

Sorting

Italy

2023-05-08

Collecting

Unknown

Unknown

-

Elastane yarn

Unknown

Italy

-

Main label

Nilörngruppen AB

Hong Kong

-

Care label

Nilörngruppen AB

Hong Kong

-

Cost, Resource and Impact Breakdown

For every garment, we not only disclose the full supply chain, but also its monetary and resource cost structure along with the resulting CO2e emissions. Impact is calculated in kg of climate change CO₂ equivalent. Figures refer to garment production (raw material to finished garment) and exclude post-purchase lifecycle stages (shipping, use phase, end of life).

| Component | Cost | Co2 | Water | Energy |

|---|---|---|---|---|

| Assembly | 17.8 EUR | 0.32 kg | 0.01 l | 0.84 kWh |

| Main Fabric | 33.8 EUR | 1.86 kg | 0.6 l | 5.87 kWh |

| Trims | 0.5 EUR | 0.07 kg | 0.04 l | 0.01 kWh |

| Transport | 0.6 EUR | 1.13 kg | 0.11 l | 9.51 kWh |

| Total | 52.7 EUR | 3.39 kg | 0.76 l | 16.23 kWh |

Care instructions

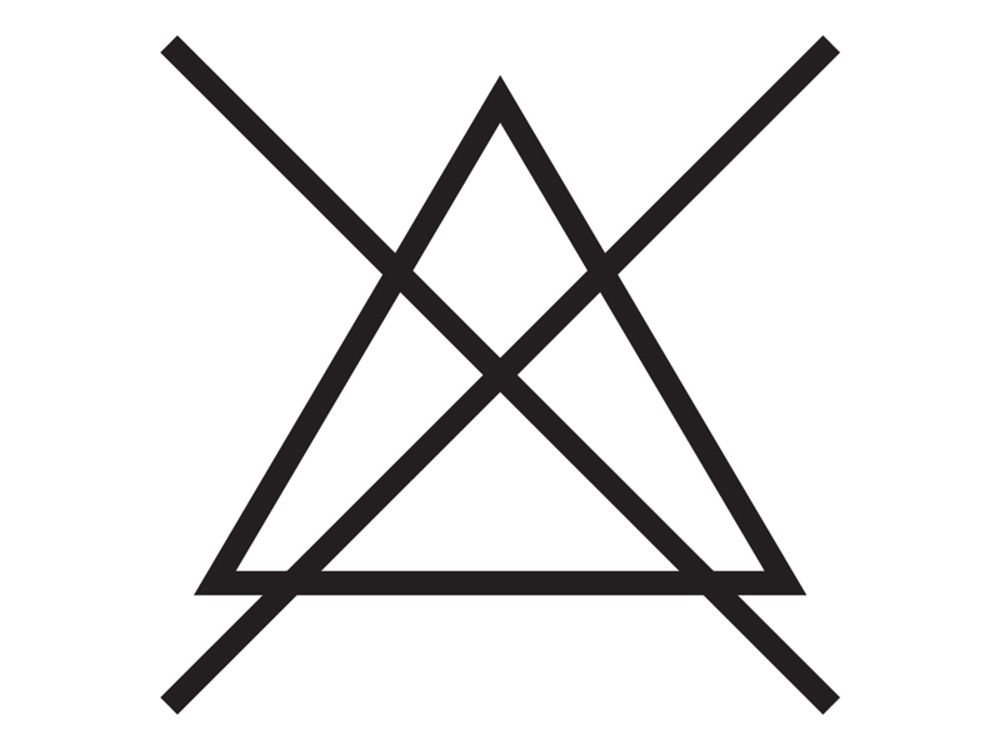

Do not bleach

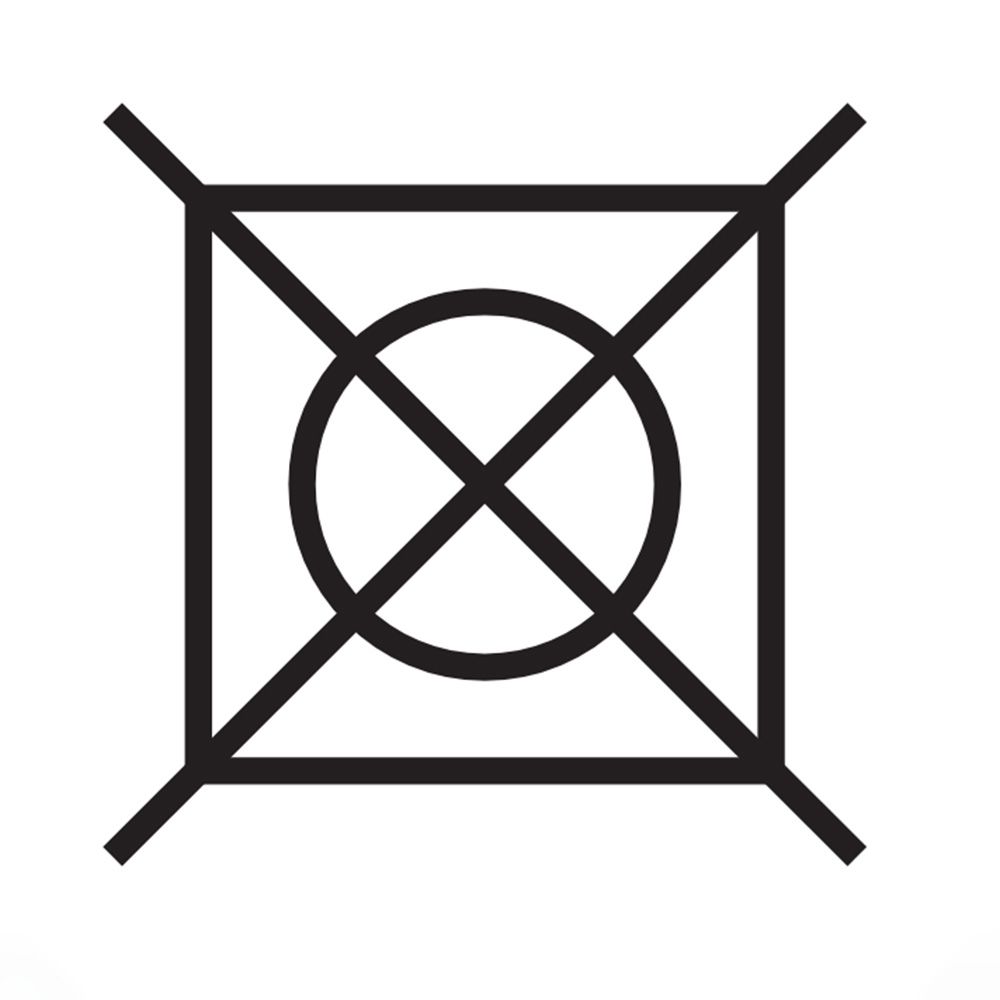

Do not tumble dry

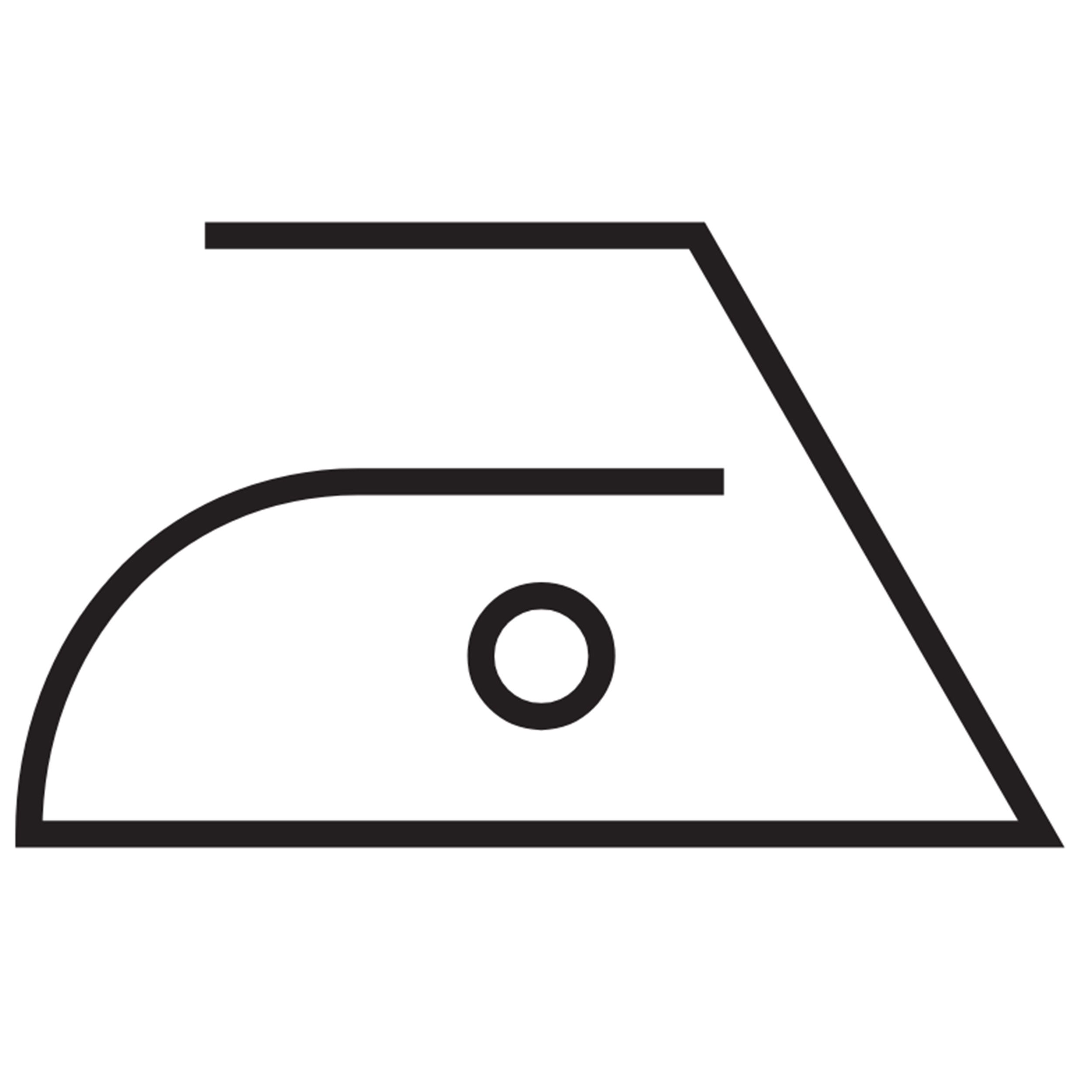

Iron at low temperature 110°C

Professional dry clean

Machine wash delicate

Garment care and repair guides

Explore our library of care guides, specific to fabrics, materials and garments, including stain treatments and repair guides below. For every product we keep spare parts and send you what you need, when you need it, at no cost.

Garment take back and resale

To extend the life of our product, we take back any unwanted Asket garments - no matter their condition or age. In exchange, you'll receive a reward voucher based on the type(s) of garments you return. Your sent in garments will be handled for resale at our Bondegatan Restore location.

Product category | Reward value |

|---|---|

Underwear | 0 CHF |

T-Shirts & Accessories | 5 CHF |

Shirts & Sweatshirts | 10 CHF |

Knitwear | 15 CHF |

Trousers, Dresses & Skirts | 20 CHF |

Outerwear | 25 CHF |