Our Journey

12 articles

Our Journey, September 2025

Asket x NATIVA™ Regenerative Wool

Our Journey, June 2025

Ten Year T-Shirt

Our Journey, May 2025

Ten Years of Asket

Our journey, May 2024

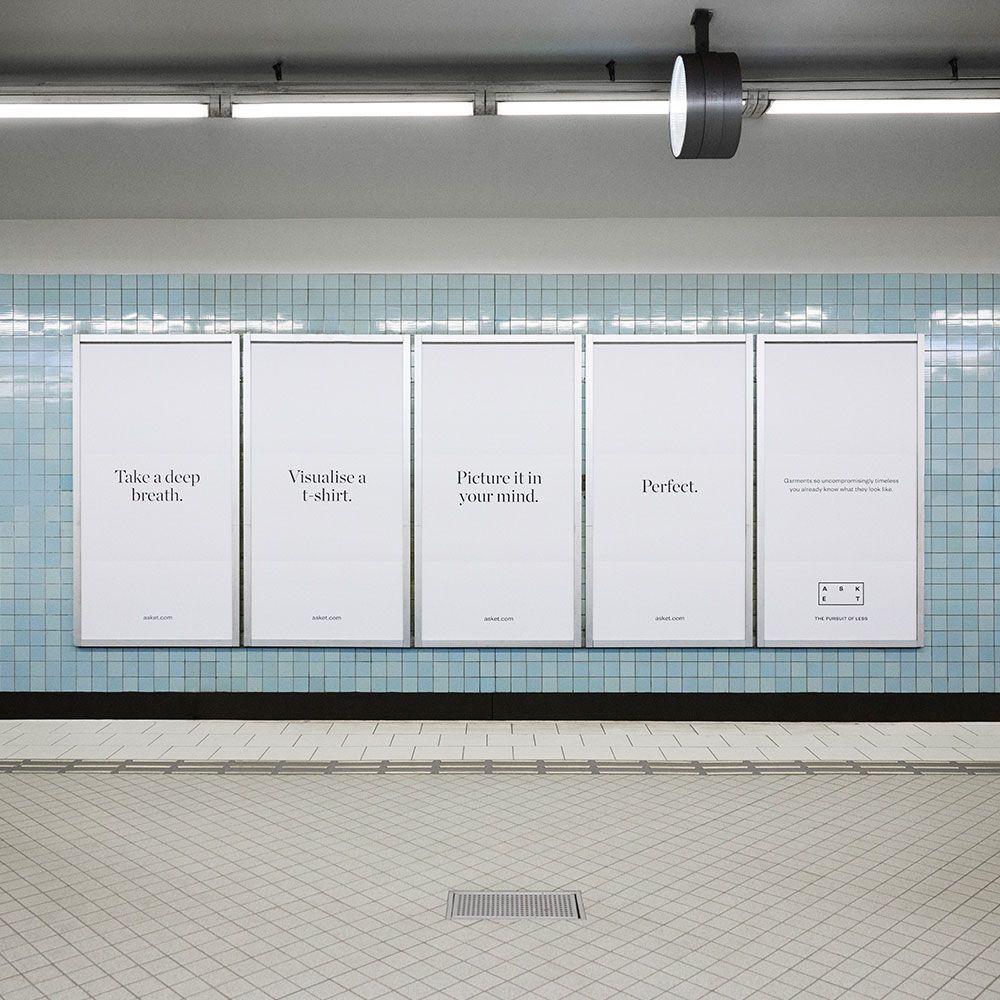

Uncompromisingly Timeless

Our Journey, July 2023

The Impact Receipt

Our Journey, Spring 2022

The New Asket HQ

Our Journey, August 2021

Organic Cotton Transition

Our Journey, March 2020

We Can’t Shop Our Way to Sustainability

Our Journey, October 2019

Fuck Fast Fashion

Our Journey, April 2019

The Mill That Fooled Us

Our Journey, May 2018

Full Traceability

Our Journey, Fall 2016

The Sweatshirt That Nearly Ruined Us